For injection molding industry 4.0, let us discuss this topic today. The injection molding industry is undergoing a significant transformation driven by Industry 4.0 technologies and smart manufacturing principles.

These advancements will reshape how plastic parts are designed, produced, and monitored—delivering higher efficiency, improved quality, and reduced costs.

From IoT-enabled machines to AI-driven process optimization, smart manufacturing in injection molding is no longer a futuristic concept—it is the standard for competitive, forward-thinking manufacturers.

This guide explores the impact of Industry 4.0 on injection molding, including key technologies, benefits, challenges, and the future of smart plastic manufacturing.

What is Smart Manufacturing in Injection Molding?

Smart manufacturing integrates advanced digital technologies into traditional manufacturing processes to enable:

- Real-time monitoring and control

- Predictive maintenance

- Data-driven decision-making

- Process optimization

In the context of injection molding, smart manufacturing combines automation, connectivity, and data analytics to improve precision, consistency, and throughput across the production line.

Industry 4.0 Overview

injection molding industry 4.0 refers to the fourth industrial revolution, characterized by:

- Interconnected machines (IoT)

- Cyber-physical systems

- Artificial intelligence (AI) and machine learning (ML)

- Big data and analytics

- Digital twins and simulation

When applied to injection molding, injection molding industry 4.0 transforms the factory into a self-monitoring, adaptive, and intelligent production environment.

Key Technologies in Smart Injection Molding

Injection molding benefits from several injection molding industry 4.0 technologies that optimize efficiency, quality, and flexibility.

1. IoT-Enabled Machines

Internet of Things (IoT) sensors can be installed on injection molding machines to:

- Monitor temperature, pressure, and cycle times in real time

- Detect deviations or anomalies in the molding process

- Provide alerts for preventive maintenance

IoT integration allows manufacturers to reduce downtime, improve efficiency, and ensure consistent quality.

2. Artificial Intelligence and Machine Learning

AI and ML algorithms analyze historical and real-time data to:

- Predict defects such as warping, sink marks, or short shots

- Optimize injection speed, temperature, and pressure automatically

- Reduce material waste and improve energy efficiency

With AI-driven injection molding, manufacturers can achieve higher first-pass yield and lower scrap rates.

3. Digital Twins

A digital twin is a virtual replica of the injection molding machine or process. It enables:

- Simulation of mold filling and cooling

- Optimization of cycle parameters before physical production

- Real-time monitoring of machine performance

Digital twins help engineers predict potential issues, reduce downtime, and fine-tune operations with minimal trial and error.

4. Predictive Maintenance

Traditional maintenance is reactive or scheduled, which can be inefficient. Smart injection molding machines use predictive maintenance to:

- Monitor vibration, temperature, and motor load

- Detect early signs of wear or malfunction

- Schedule maintenance before a breakdown occurs

This approach reduces unplanned downtime, extends machine life, and lowers maintenance costs.

5. Cloud Computing and Data Analytics

Centralized cloud systems collect data from multiple machines and production lines. Data analytics tools provide:

- Real-time dashboards

- Key performance indicators (KPIs) such as OEE (Overall Equipment Effectiveness)

- Historical trend analysis for process improvement

Cloud integration enables scalable, multi-site production monitoring and decision-making.

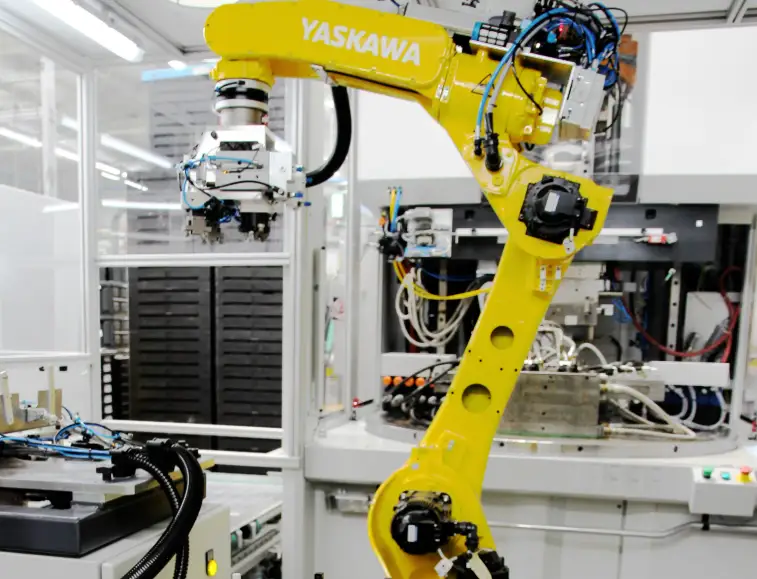

6. Robotics and Automation

Advanced robotics in injection molding include:

- Automated part handling and assembly

- Robot-assisted demolding

- Secondary operations like trimming, inspection, or packaging

Automation reduces labor costs, human error, and cycle time, while improving safety in the manufacturing environment.

Benefits of Smart Manufacturing in Injection Molding

Injection molding industry 4.0 adoption brings tangible benefits to injection molding operations.

1. Enhanced Production Efficiency

- Real-time monitoring and AI optimization reduce cycle times

- Predictive maintenance minimizes unplanned downtime

- Automated material handling and post-processing speed up throughput

2. Improved Product Quality

- Digital twins and process simulation ensure accurate mold filling and cooling

- Sensors detect anomalies, preventing defective parts

- AI-driven optimization maintains tight tolerances and consistency

3. Reduced Waste and Energy Consumption

- Smart monitoring identifies energy-intensive processes

- Material usage is optimized through precise injection control

- Scrap rates decrease with predictive defect detection

4. Faster Time-to-Market

- Digital workflows and simulation reduce prototyping and trial runs

- Process adjustments can be made remotely in real-time

- Startups and OEMs can iterate on designs rapidly with confidence

5. Data-Driven Decision Making

- Production data provides actionable insights for managers

- Trend analysis identifies bottlenecks and improvement opportunities

- Real-time dashboards improve responsiveness and operational visibility

Applications of Smart Injection Molding

Smart manufacturing transforms multiple sectors that rely on injection-molded plastics.

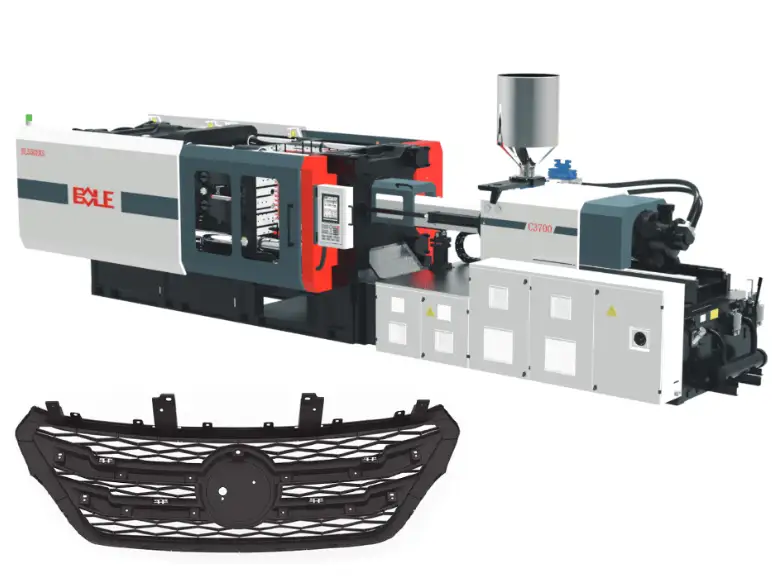

1. Automotive Industry

- Production of interior and exterior components with tight tolerances

- Predictive maintenance reduces costly downtime in high-volume lines

- Digital twins simulate mold filling to reduce cycle failures

2. Medical Devices

- High-precision parts like surgical tools, housings, and disposables

- Traceable quality control with IoT-enabled sensors

- Rapid adjustments for small-batch production

3. Consumer Electronics

- Transparent, functional, and intricate housings

- Robotics and automated post-processing for consistent quality

- AI optimization ensures minimal waste and accurate tolerances

4. Packaging Industry

- Complex bottle, lid, and container designs

- Digital monitoring improves efficiency in high-volume lines

- Smart sensors track production for regulatory compliance

5. Industrial and Engineering Components

- Functional, high-strength parts for machinery and equipment

- Predictive maintenance ensures uninterrupted production

- Automation reduces manual handling of heavy components

Challenges in Implementing Smart Manufacturing for Injection Molding

While the benefits are significant, there are challenges to overcome:

- High Initial Investment

- IoT sensors, AI systems, robotics, and cloud infrastructure require capital.

- Data Management

- Handling and analyzing massive volumes of production data can be complex.

- Skilled Workforce Requirement

- Engineers must understand both injection molding and advanced digital systems.

- Integration with Legacy Systems

- Older machines may need retrofitting or replacement to be fully connected.

- Cybersecurity Concerns

- Connected machines are vulnerable to cyber threats if not properly protected.

Key Steps for Adopting Smart Manufacturing in Injection Molding

- Assess Current Operations

- Identify machines, processes, and areas where automation or monitoring will have the highest impact.

- Invest in IoT and Sensors

- Equip injection molding machines with real-time sensors for temperature, pressure, and cycle monitoring.

- Implement Data Analytics Platforms

- Centralize data collection and visualization through cloud-based dashboards.

- Integrate AI and Machine Learning

- Use AI to predict defects, optimize processes, and reduce scrap.

- Train Workforce

- Ensure operators, engineers, and managers are skilled in Industry 4.0 tools and data interpretation.

- Scale Gradually

- Start with pilot lines, then expand to the entire factory for controlled implementation.

Future Trends in Smart Injection Molding

- Edge Computing: Real-time process control at the machine level without relying solely on the cloud

- Additive Manufacturing Integration: Combining 3D printing with injection molding for hybrid workflows

- Sustainability and Energy Monitoring: Smart systems track energy use and environmental impact

- Self-Optimizing Molds: Adaptive molds that automatically adjust cooling and injection parameters

These trends indicate that the next decade will see injection molding become more automated, efficient, and intelligent than ever before.

Conclusion

Smart manufacturing and injection molding industry 4.0 technologies are redefining the injection molding industry, offering benefits such as improved efficiency, enhanced product quality, reduced waste, and accelerated time-to-market.

From IoT-enabled machines and AI optimization to digital twins and predictive maintenance, smart injection molding enables manufacturers to produce high-precision, high-performance plastic parts in a more flexible, cost-effective, and sustainable way.

Companies adopting injection molding industry 4.0 principles are gaining a competitive advantage, staying ahead in automotive, medical, consumer electronics, packaging, and industrial sectors.

The future of injection molding lies in data-driven, interconnected, and adaptive production, marking a significant evolution from traditional manufacturing to a smart, intelligent, and fully integrated system.